|

Laser Cutting

Laser Tubes-1

Laser Tubes-2

Laser Tubes-3

|

Custom Laser Cutting Overview

Welcome to CustomLaserCutting.com! Our custom laser cutting service is ideal for making custom parts quickly and economically for any project. You can get started with making custom laser-cut parts for only $25. If you are in a hurry, we can have custom plastic parts delivered to your door as soon as the next day!

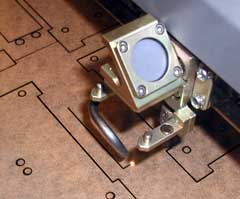

Capabilities and limitations of custom laser cutting

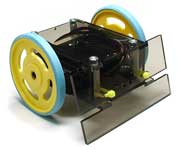

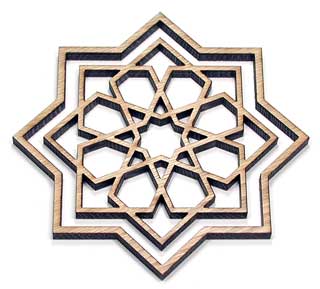

Our custom laser cutting service gives anyone the ability to create custom parts from a variety of materials. Laser cutting also allows you to realize intricate designs that are too complex for creating by hand. We can laser cut almost anything you can draw, including sharp angles, smooth curves, small screw holes, and complex lace designs, and we can also laser engrave text, logos, and photos on to your parts. We mainly laser cut custom plastic parts, but we can also make custom wood, rubber, and foam parts (sorry, no PVC, vinyl, or metals). We can only laser cut two-dimensional parts, but you can create three-dimensional designs from flat pieces such as the sumo robot chassis shown here. Our laser cutters can cut up to 1/2" acrylic (Plexiglas) with a maximum part size of 35" x 49.5". For more details, please see our page about laser cutting capabilities, limitations, and issues. Our custom laser cutting service gives anyone the ability to create custom parts from a variety of materials. Laser cutting also allows you to realize intricate designs that are too complex for creating by hand. We can laser cut almost anything you can draw, including sharp angles, smooth curves, small screw holes, and complex lace designs, and we can also laser engrave text, logos, and photos on to your parts. We mainly laser cut custom plastic parts, but we can also make custom wood, rubber, and foam parts (sorry, no PVC, vinyl, or metals). We can only laser cut two-dimensional parts, but you can create three-dimensional designs from flat pieces such as the sumo robot chassis shown here. Our laser cutters can cut up to 1/2" acrylic (Plexiglas) with a maximum part size of 35" x 49.5". For more details, please see our page about laser cutting capabilities, limitations, and issues.

We started our laser cutting service to create custom robot parts, but of course, any custom part is welcome — our laser cutting service is great for anyone with a project requiring custom parts!

Materials for Laser Cutting

We can laser cut plastics, woods, rubbers, foams, and papers as long as they do not contain chlorine. Depending on the material, there is usually no limit to the thinnest sheet we can cut, and the thickest sheet we can cut is typically 1/2" (12 mm). We stock acrylic, ABS, Mylar, PETG, and styrene, and you are welcome to mail us material or have suppliers ship us material directly.

Ordering and pricing custom laser-cut parts

To order custom laser-cut parts, all you have to do is draw your part in CAD or vector-graphics drawing software, decide which laser cutting materials to use, submit the file on our web site for a quote, and respond to the quote with a phone call or PayPal payment to start the job. Our standard turn time is 5 business days, and we also offer expedited laser cutting. We can even ship the same day, so you can have your custom part in hand as soon as tomorrow morning!

If you prefer, you may place a small, initial order to test a design, and follow up with a larger order once you verify the parts (we do provide price breaks for larger orders). To get a rough idea of the cost for your parts, please see our laser cutting pricing.

Creating files for laser-cut parts Creating files for laser-cut parts

We can use most standard vector-graphics file types for laser cutting parts including DXF, DWG, PDF, CDR, AI, and SVG (we use TurboCAD version 11 and Corel DRAW version 12). If you do not have access to software for drawing your parts, we suggest downloading free drawing software. We also might be able to draw your part for you for $60/hr; please submit your sketch or written description through our quote request form (any file that we can open is fine). For more information, please see our topics on laser cutting file set up.

Getting started with custom laser cutting

To get started with creating your own custom laser-cut parts, please read the following topics. If you are ready to request a quote, you can go straight to our quote request form. If you have any questions about our custom laser cutting service, please contact us.

>>Product Description

We produce sealed CO2 laser tube 20W, 30W, 40W, 50W, 60W, 70W, 80W, 100W, 120W, 130W,150W with excellent quality.

CO2 laser tube, as one of key laser parts, is widely used in industrial cutting and engraving non-metallic materials, such as printing engraving, plexiglass, leather, wood products, bamboo products and a variety of materials buttons, as well as carving and cutting on keyboard and etc.

CO2 laser tube we provided adopts the special processes and has the following advantages:

Professional provide medium-low power CO2 glass sealed Laser Tube widely used to kinds of laser cutting machine, laser engraving machine, co2 laser cutter, laser engraver etc. Laser power range is 10 watts – 150 watts, the length is from 400MM to 2000MM. The main advantage of our laser tubesis perfect spot mode, steady, long lifetime etc. And we can offer the technology consulting and installation guide before your purchase in order to purchase the best product for you.

>>Features

The equipment components are horny glass, resonance and electrode horny glass: this Part is make up by discharge tube , water-cooling set , gas storage set and trachea with GG17 material. CO2 Seal laser instrument is three layers pipe. The inside is Discharging tube, the middle is water-purify set and the out layer is gas storage. go back trachea is it is it is it in charge of and store the trachea to discharge to feed through to used for resonance: This part is make up by all and output speculum. optical glass as basis, golden membrane surface, the reflection rate of the gold membrane speculum near 10.6um is more than 98%; Output speculum adopt 10.6um of radiation as basis as well as the multi-layer medium membrane.

Part of the electrode: CO2 laser instrument generally adopts the cold cathode, cylindrical shape, the negative pole material selection has great influence on life-span and the basic requirement is that low sputter rate, small gas absorption rate and used metal material is the nickel.

>>Usage

1. Make sure not to connect line of electrode by mistake.

2. Connection the cool water pipe, input from cathode and output from the anode and no leak conservation storage before using.

3. It’s better to fit checking equipment in water circulation system in case fault caused by water-break. For details please consult supplier.

>>Keep & Maintenance

1.Please check water circulation and make sure no bubble before using.

2. Check output speculum of negative pole to make sure no dust or grease spot, scrub away them with aether cotton to avoid influencing life-span caused by power and facula.

>>Performance

Sealed off CO2 laser technology parameters table

|

Model

|

Length(mm)

|

The main parameters of performance indicators(Wavelength10.6µm)

|

|

Outside Diameter (mm)

|

Laser Spot (mm)

|

Triggering Voltage (kv)

|

Operating voltage (kv)

|

Triggering Current(mA)

|

Operating Current (mA)

|

Output power (watt)

|

Stability (%)

|

|

MTS-T20

|

500

|

Ø50±2

|

≤3

|

12-13

|

8-9.5

|

3-5

|

14-16

|

≥18-21

|

10

|

|

MTS-T25

|

600

|

Ø50±2

|

≤3

|

13-14

|

9-10

|

4-5

|

15-17

|

≥20-23

|

10

|

|

MTS-T30

|

700

|

Ø50±2

|

≤3

|

14-15

|

10-10.5

|

4-5

|

15-18

|

≥23-30

|

10

|

|

MTS-T30S

|

800

|

Ø50±2

|

≤3

|

18-20

|

11-12

|

5-6

|

18-22

|

≥23-30

|

10

|

|

MTS-T40

|

850

|

Ø50±2

|

≤3

|

19-21

|

12-13

|

5-6

|

18-22

|

≥32-42

|

10

|

|

MTS-T45

|

950

|

Ø50±2

|

≤3

|

20-22

|

13-14

|

5-6

|

18-22

|

≥38-48

|

10

|

|

MTS-T50

|

1000

|

Ø50±2

|

≤3

|

21-22

|

14-15

|

5-6

|

18-22

|

≥40-50

|

10

|

|

MTS-T60

|

1200

|

Ø50.55.60±2

|

≤4

|

21-23

|

14-16

|

5-6

|

18-22

|

≥58-62

|

10

|

|

MTS-T70

|

1250

|

Ø55.60±2

|

≤4

|

22-24

|

15-17

|

5-6

|

18-22

|

≥62-70

|

10

|

|

MTS-T75

|

1500

|

Ø55.60±2

|

≤5

|

23-25

|

16-18

|

6-7

|

22-25

|

≥65-75

|

10

|

|

MTS-T80

|

1600

|

Ø55.60±2

|

≤5

|

24-26

|

17-19

|

6-7

|

22-25

|

≥80-90

|

10

|

|

MTS-T100

|

1650

|

Ø75±2

|

≤6

|

26-28

|

18-20

|

7-8

|

25-28

|

≥100-110

|

10

|

|

MTS-T130

|

1850

|

Ø80±2

|

≤6

|

26-28

|

19-21

|

7-8

|

25-28

|

≥120-130

|

10

|

|

MTS-T150

|

2000

|

Ø80±2

|

≤8

|

26-28

|

20-22

|

9-10

|

25-28

|

≥140-150

|

10

|

Laser tube display

Module number : MTS-LT60-100

|

|

|

|

|

|

| Model No.︰MTS-2361 |

|

|

|

|

|

|

Mactron Brand Long Lifetime co2 laser tube adopt new technique of production and inflation formula for co2 gas, to ensure the high quality and stability of glass laser tubes. The lifetime of laser tube is up to 8000 hours, laser power is from 80 watts to 180 watts, it is very popular in thickness materials cutting.

1. Specification:

|

Rated Power (watts)

|

80

|

100

|

130

|

150

|

|

Max. Power (watts)

|

90

|

120

|

150

|

180

|

|

Full Length (mm)

|

1200

|

1400

|

1650

|

1850

|

|

Diameter (mm)

|

80

|

80

|

80

|

90

|

|

Catalyze

|

Yes

|

Yes

|

Yes

|

Yes

|

|

Triggering Voltage (KV)

|

20

|

24

|

28

|

30

|

|

Operating Current (mA)

|

27

|

28

|

29

|

30

|

|

Span Life (hours)

|

8,000

|

8,000

|

8,000

|

8,000

|

|

Warranty Period (months)

|

6

|

6

|

6

|

6

|

2. Working Performance:

● Cutting function.

● Engraving function: Auxiliary engraving, when the working current is 4mA and the tube is in the state of preionization, the laser can be used for high-frequency impulse engraving.

3. Important Notice:

|

For this type CO2 Laser Tubes, do not clean the exterior surface of the output widow mirror with tools such as tampon; otherwise the output power will be seriously affected. The followings are the designated methods to clean up pollution in the exterior surface of window mirror:

1) When the mirror is polluted, do not turn on the laser.

2) Blow the mirror surface sideway with air blower.

3) Spray the pure alcohol on the mirror surface with sprayer.

4) Turn on the laser after the alcohol gets fully volatilized.

5) If the methods above don't work effectively, it is necessary to ask for the professional to use tampon with alcohol to clean the mirror surface from middle to edge. The best solution is to prevent the window from being polluted.

Attention: longlife Laser Tube is forbidden to clean the mirror with acetone.

The screw in the front and back ends of the laser tube is not allowed to be moved, otherwise the out power will be declined and even the tube may be scrapped.

Put the acryl 300mm far away from output mirror, when testing the laser spot.

4. Safety:

The laser beam is invisible light. Please wear protective glasses when debugging the laser. The positive pole is in high voltage. Pay attention to the security marks.

5. Storage and Transportation Requirement:

Pour out cooling fluid in the event of storage and transportation, and cover the output terminal with a dust-proof plastic bag. The storage environment is 2-40℃, and the requested humidity is 10-60%. Pack the laser as in the original way.

Important notes: it is requested to cement the sponge together with laser tube to prevent the tube vertically sliding during transportation. The sponge in the side of output mirror must be 70mm beyond it, and the sponge in the side of reflecting mirror must be 50mm wider.

|

|

130 Watt Co2 Glass Laser Tube

|

|

|

|

|

|

CO2 130 watt laser tube is used for cutting thickness non-metal materials,such as wood, acrylic, PVC sheet, leather etc

We produce sealed CO2 laser tube 20W, 30W, 40W, 50W, 60W, 70W, 80W, 100W, 120W, 130W,150W with excellent quality.

CO2 laser tube, as one of key laser parts, is widely used in industrial cutting and engraving non-metallic materials, such as printing engraving, plexiglass, leather, wood products, bamboo products and a variety of materials buttons, as well as carving and cutting on keyboard and etc.

|

CO2 laser tube we provided adopts the special processes and has the following advantages:

1. The laser output power density is high, and the light beam is centralized;

2. High efficiency;

3. The speed of response for the laser pulse discharge is quick;.

4. Laser beam after focusing is sharp;

5. The width of the focusing beam is narrow;

6. High resolution;

7. Clear figures or words. |

| |

|

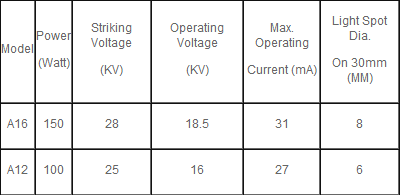

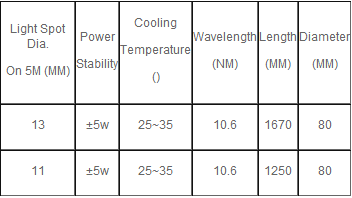

| 150 Watt High Power Co2 Glass Laser Tube |

|

|

|

|

|

|

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

|