Prototyping / Batch service for 1 Layer , 2 Layer , through hole 4 Layer , 6 Layer PCB

Professional skill : we checked your gerber file and raise question ( if there is ) before production

Kind customer service : we suggest the best way such as panelize your PCB for fabrication to lower your cost

Attractive price : A -flexible price for actual gerber size and quantity ; B -VIP price for VIP customer; C- extra-low price for standard PCB prototyping

Gerber Rulers

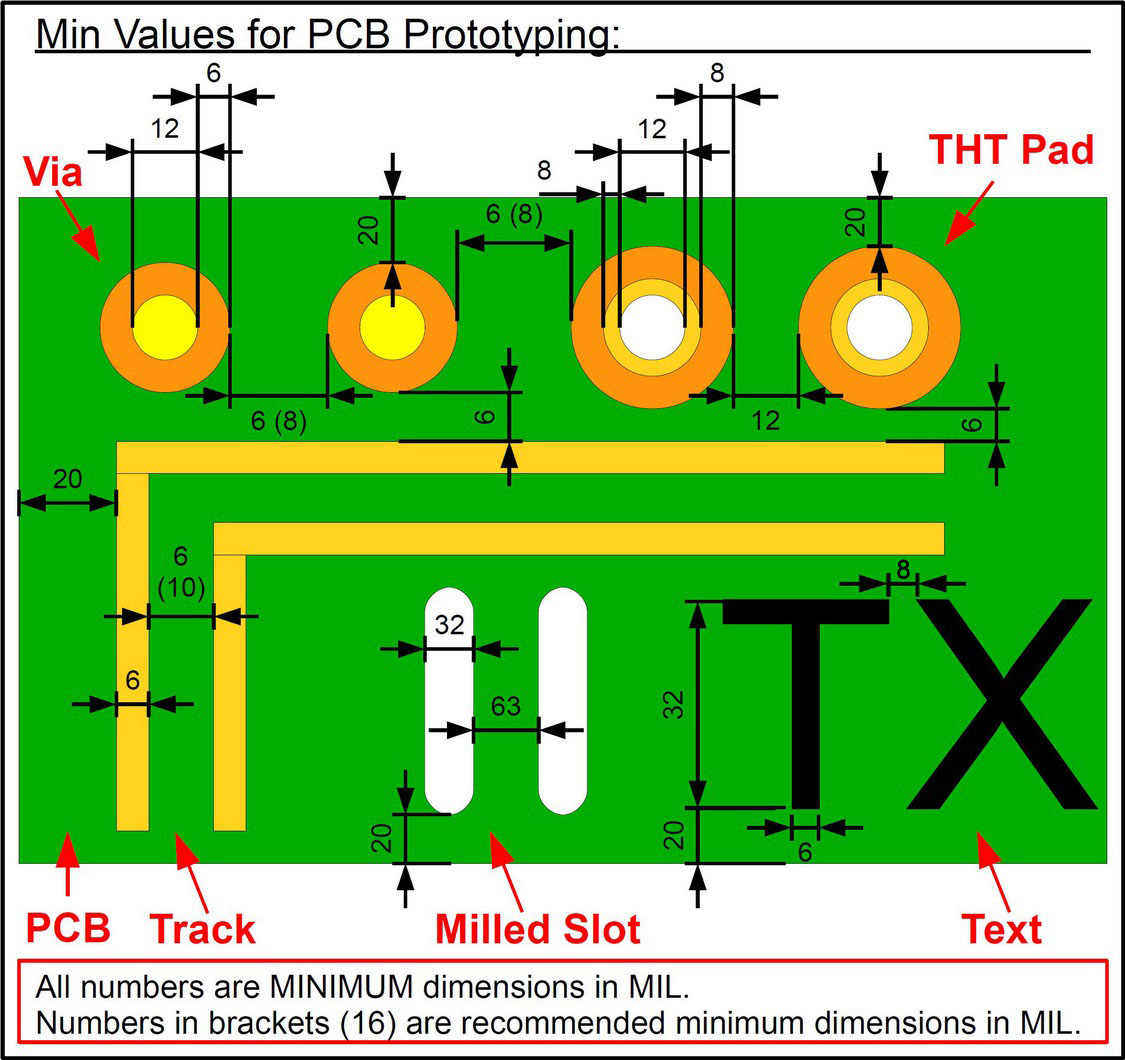

Gerber Files: If you are ordering the first time make sure that your design is comply with following min/max limits:

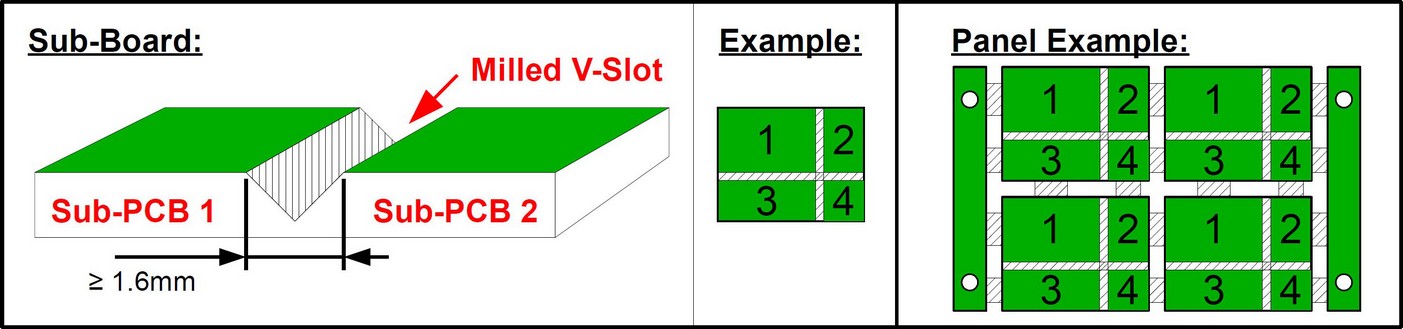

Separated Sub-Boards: for seperating boards please use a slot according to following pictures. Drilling holes or other methods for seperating boards will be NOT accepted. Boards which are seperated only by silk-screen are counted as sub-boards and have to be payed extra. Junctions between V-Slots are always crossing (X). For other junctions like (T) or (L) you need to use the normal milling and not the V-Slot.

Panels: For higher quantities (depending on the used area) we will combine your PCBs automatically to a panel. If you don ot want it or want to define your own panel then contact us before ordering at sales@smiery.com .

E-Test: All PCBs are getting a 100% AOI (Automated Optical Inspection) to make sure that all tracks and pads are connected.

In addition to this the PCBs can be tested by a flying probe to make sure that all vias are connected, because this is not visible by the AOI.

1-layer PCBs don't need this tests because there are no vias.

4- and 6-layers will be tested always 100% with a flying probe.

For 2-layer PCBs we provide 100% e-test .

Click here to learn the PCB price

Responsibility: We are not taking any responsibility for your Gerber files. We are using them as-they-are for producing the PCBs, so make sure that they comply with all limits and standards.