|

PCBA process

Battery Pro

PCB 24h/48

|

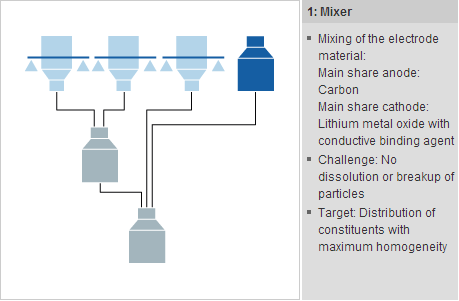

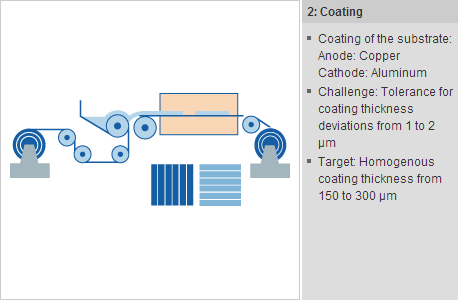

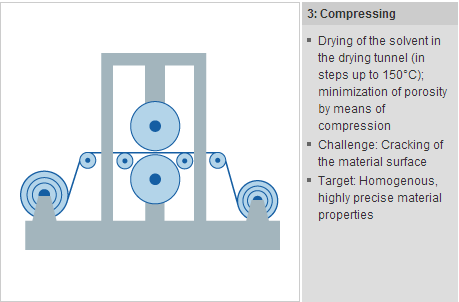

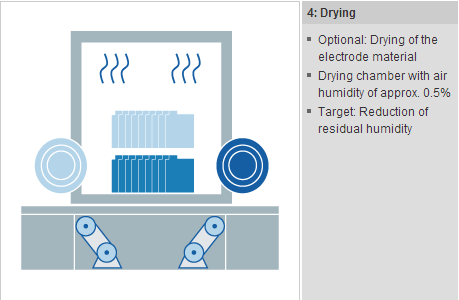

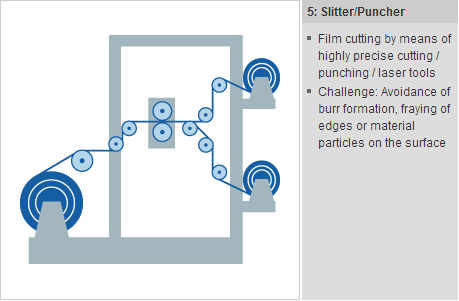

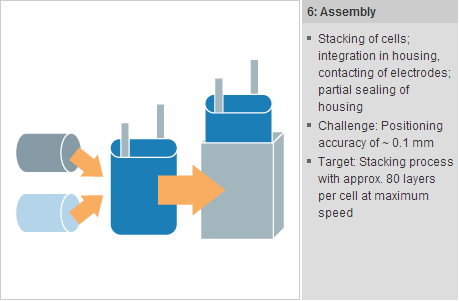

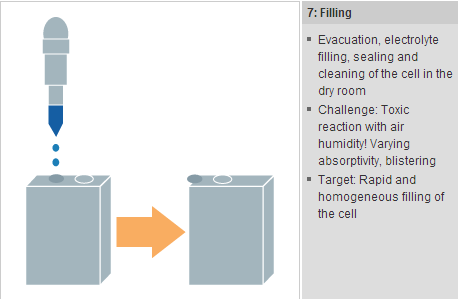

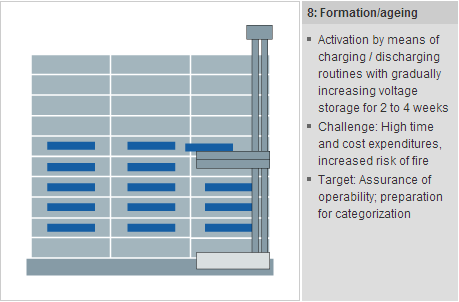

The manufacture of electrodes, cells and modules/packs for large-format power batteries is still in its infancy. One thing, however, is already perfectly clear: the battery manufacturing operation needs to become faster and less expensive if lithium-ion energy storage technology is to establish itself successfully in the target markets. The sensitive chemistry of the cells means that these cost and time savings absolutely cannot come at the expense of quality, which needs to remain very high. The solution, therefore, lies in fully automating and integrating production lines.

The automation portfolio needs to provide comprehensive support for the development process, from the pilot system to in-line integration. Totally Integrated Automation from our factory makes it possible to optimize all processes throughout the production line and across the entire lifecycle of the plant. Uniform data management, engineering and communication standards ensure that all production steps, from electrode manufacturing to cell assembly to pack mounting and final quality tests, are optimally coordinated.

>>Speed-up service for 2 Layer and 4 Layers PCB helps you to save much time . You can buy time with your money .

| 24 h speed-up manufacturing for 2 Layers PCB |

| MI: |

2014-12-01 23:03 |

Etching: |

2014-12-02 07:15 |

| Material Cutting : |

|

AOI: |

2014-12-02 07:19 |

| Inner Layers : |

|

Solder Mask: |

2014-12-02 10:04 |

| Inner AOI : |

|

Silk Screen: |

2014-12-02 11:41 |

| Pressing: |

|

Surface Treatment |

|

| Drilling : |

2014-12-02 01:30 |

Outline: |

2014-12-02 17:34 |

| Plating: |

2014-12-02 03:59 |

E-test: |

2014-12-02 16:37 |

| D/F: |

2014-12-02 05:12 |

FQC Package: |

2014-12-02 17:34 |

| 48 h speed-up manufacturing for 2 Layers PCB |

| MI: |

2014-10-28 20:55 |

Etching: |

2014-10-29 05:01 |

| Material Cutting : |

2014-10-28 21:38 |

AOI: |

2014-10-29 05:06 |

| Inner Layers : |

|

Solder Mask: |

2014-10-29 06:20 |

| Inner AOI : |

|

Silk Screen: |

2014-10-29 06:49 |

| Pressing: |

|

Surface Treatment |

2014-10-29 16:12 |

| Drilling : |

2014-10-29 00:02 |

Outline: |

2014-10-29 19:40 |

| Plating: |

2014-10-29 01:47 |

E-test: |

2014-10-29 17:49 |

| D/F: |

2014-10-29 02:33 |

FQC Package: |

2014-10-29 19:39 |

| 48 h speed-up manufacturing for 4 Layers PCB |

| MI: |

2014-10-28 22:37 |

Etching: |

2014-10-30 03:34 |

| Material Cutting : |

2014-10-28 22:54 |

AOI: |

2014-10-30 04:10 |

| Inner Layers : |

2014-10-29 03:06 |

Solder Mask: |

2014-10-30 06:07 |

| Inner AOI : |

2014-10-29 04:50 |

Silk Screen: |

2014-10-30 06:31 |

| Pressing: |

|

Surface Treatment |

2014-10-30 11:47 |

| Drilling : |

2014-10-29 16:31 |

Outline: |

2014-10-30 15:05 |

| Plating: |

2014-10-29 21:58 |

E-test: |

2014-10-30 13:38 |

| D/F: |

2014-10-29 23:02 |

FQC Package: |

2014-10-30 15:05 |

4 Layers PCB is not available for 24 h speed-up service , 72 h speed-up is vailable .

>>FPC and 6 layers PCB are available to speed-up service , contact us for more details if you need .

>> Time Schedual

We take speed-up order from Monday to Saturday ( China holidays excluded ) .Our factory comes to process the speed-up gerber files after 18:00 ( China local time ) every day ( Sunday excluded ) , payment must be make before 17:00 .

|