.gif) There are two types of gold finish: Electroless Nickel Immersion Gold (ENIG) as a surface finish for the whole PCB, and hard plated gold over plated nickel for edge-connector fingers. Electroless gold gives excellent solderability, but the chemical deposition process means that it is too soft and too thin to withstand repeated abrasion. Electroplated gold is thicker and harder making it ideal for edge-connector contacts for PCBs which will be repeatedly plugged in and removed. There are two types of gold finish: Electroless Nickel Immersion Gold (ENIG) as a surface finish for the whole PCB, and hard plated gold over plated nickel for edge-connector fingers. Electroless gold gives excellent solderability, but the chemical deposition process means that it is too soft and too thin to withstand repeated abrasion. Electroplated gold is thicker and harder making it ideal for edge-connector contacts for PCBs which will be repeatedly plugged in and removed.

For R&D member , we recomend them to use ENIG , because it is inexpensive .When we process the gerber file of gold finger , we usually remove the solder mask bridge (which us filled between in 2 fingers ,in order to make the connection better . In my memery ,there is once a R&D member send me a gerber file with solder mask bridge remained , unfortunately , our factory failed to notice the solder mask bridge and fabricate the boards following the gerber design .So when the R&d member show his un-pleasure , we can do nothing but show sympathy with him .

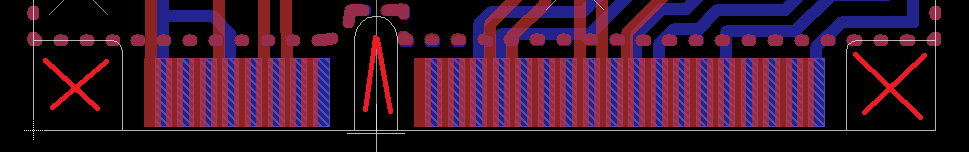

After that , he asked me , how to avoide the same issue . After checking his gerber file ,I finally concluded that dwraw a big rectangle and put on solder mask layer ,so the rectangle can cover all the fingers .

Why should the solder mask design be drown by this way ? It concerns the PCB manufacturing .When the copper design is transferred to the copper , the copper will be covered with solder mask fully first , then how can the solder pads be exposed to the air ? that needs the solder mask film .Through covering the copper by soder mask film (please note ,the solder mask registration tolerance is +/-2mil) accuracy , and send the plate to Exposure and development process , to make the SMD exposed to air .After Chemical reaction,where there is a solder rectangle ,the solder resist is removed . So if you want to have the solder resist on the fingers be removed , you should make sure all the pads are covered with solder mask pads .

.gif)

|